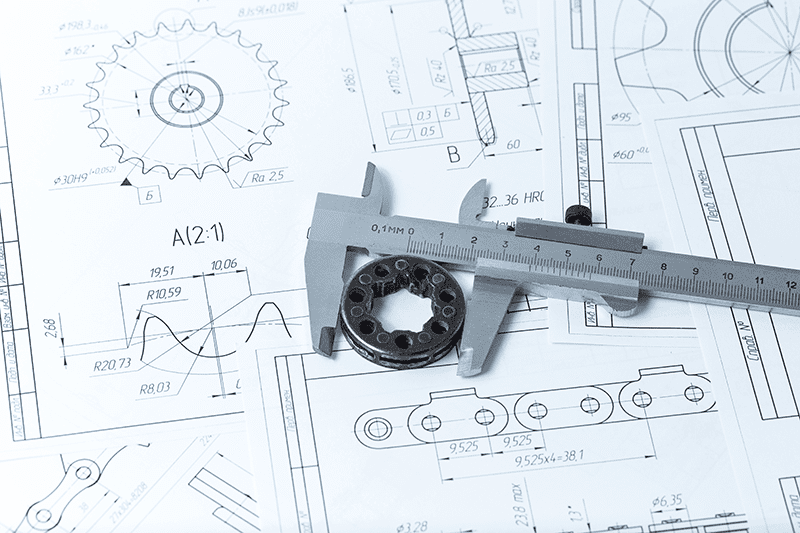

About Our Engineering Services

Project management

We project manage the work given to us and discuss timelines with the customer before commencing any work. All projects get the full attention from cradle to grave. The process is simple for the customer and we will take all the initiative to complete all the daunting tasks to result in a complete solution for the requirement.

Engineering work requires systematic approach to solutions and hence Lean methods, Kaizens and Value stream mapping are useful tools. In addition to others, we use methodologies of

Prince II and Agile project management to deliver the required work.

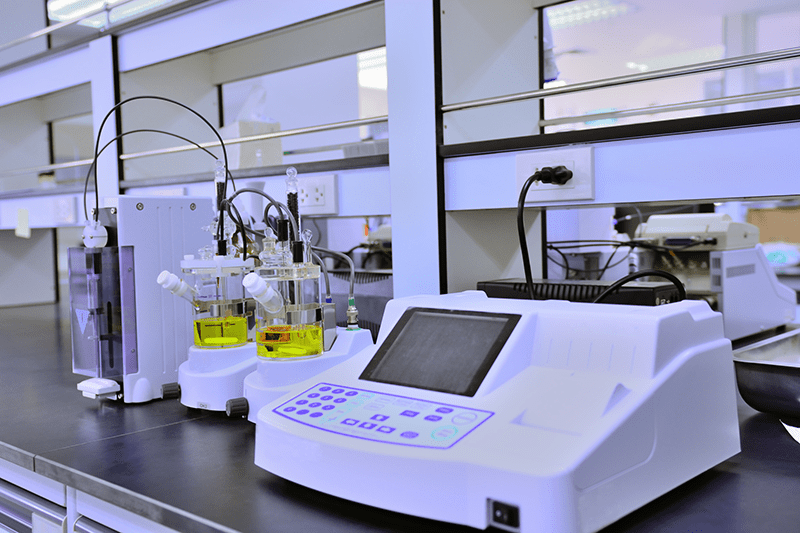

Compound Formulations

We have the technical expertise to develop compounds for various applications in all industries. We can arrange for samples to be prepared and tested for your approval. Typical applications include abrasion resistance, pharmaceutical compliant, FDA compliant, WRAS compliant and many others. The Materials include Masterbatched Thermoplastics, Elastomers, Thermosetting plastics, Alloys and composites.

Please call to discuss your requirements.

Testing and Evaluation of materials and components

The testing and evaluation work can be performed for the customer to the level of detail required.

At this stage collaboration with other bodies including Universities, government bodies and other test centres can be utilised to get the correct information. The work can involve a number of different protocols that can encompass Standards, Regulations and Company procedures and requirements.

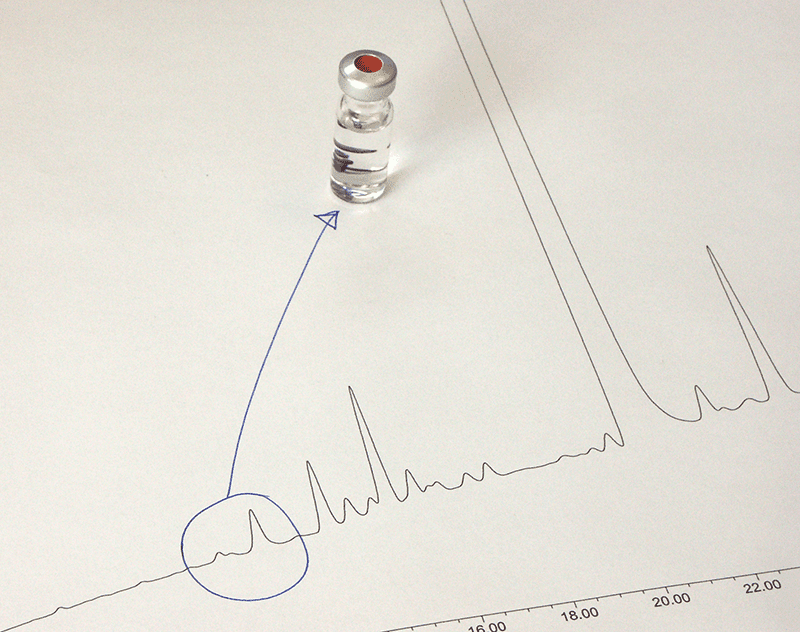

Composition Analysis

The chemical composition of a substance can be determined using various techniques. The analysis solves chemical issues by identifying the composition. This can lead to information to determine the influence of the chemicals present to the contact media. The analysis helps with R&D projects and the day to day production can be quality controlled using these techniques. Typical analysis can be for contamination including chemical trace and elemental trace.

Raw Material Supplies

We can supply raw materials for Polymers and other materials if required. These include Sustainable Polymers that can be Bio-based, Chemically recycled, mechanically recycled, Mass balanced, Hydrocarbon based or even alternative green materials to replace existing ones. Please query with us.

Failure Analysis

There are several methods of carrying out a process of collecting and analyzing data. It enables designers and manufacturers to understand the root cause of the product or process in question. Several methods are utilized. Some include:

FMEA – Failure Mode Effect Analysis

PFMEA – Process Failure Mode Effect analysis

DFMEA – Design Failure Mode and Effect Analysis

HAZAN and HAZOP – Hazard Analysis and Hazard Operability Analysis used commonly in Chemical plants

Mechanical and Environmental Testing

Material mechanical property testing involves an evaluation of the properties like Tensile strength, Elongation, Modulus, Hardness, Density, Fracture toughness, Elasticity, Impact resistance and Fatigue limit. Various material exhibit different properties and these can be tested. Accelerated ageing of the component or material will provide information on performance and the degradation of these properties over time. Exposure to various environmental conditions can be replicated to actual conditions.

The tests can be for compliance to ASME BPE standards, ASTM, BS ISO and DIN.

Please call to discuss your requirements.

Analytical Evaluation

In line with compositional testing, typical methods used are Fourier transform infrared spectroscopy (FTIR), UV radiation, Gas chromatography-mass spectrometry (GCMS), Liquid chromatography (HPLC and UPLC), Scanning Electron Microscopy(SEM) and Plasma spectrometry. Other methods include Thermogravimetric Analysis (TGA), Evolved Gas Analysis (EGA), Dynamic Mechanical Analysis (DMA) and Laser Flash Analysis (LFA).

Extractables and Leachables

The Pharmaceutical industry requires this information and it is important that tests are carried out on the material or component in contact with the media being processed. There are concerns of leachants and extractables from Plastic, Elastomer, Metal and Glass components into the media. Analytical tests can be conducted in line with ASME BPE protocols to ensure that the product meets the requirement and does not contaminate the process media.

Regulatory Testing

Other testing in-line with regulatory requirements can be conducted to ensure the standards are met. Typical standards include BS ISO, ASTM, DIN, MIL-G and many others.

Component Sub-contracting and In-house Manufacture

At R&I Management Consulting Ltd we can manufacture some parts depending on complexity and equipment required but these can be subcontracted for completion.

Please enquire about your requirements.